Mixers

High-performance industrial and chemical tank mixers need to be designed and specified for each individual application and process that highlights the importance of mixing in process control. Industrial mixing machinery for tanks or process vessels includes top and bottom entry batch mixers, high shear mixers, and chemical mixers that require rigid mounts and may involve sealed or pressurized systems. Eastern Reliability offers a variety of top-mounted ANSI Flange, Tri-clamp, and plate mount models which are highly customizable including motor, gearbox, seal, and impeller options that are available in top and side entering configurations with mounting arrangements for any tank application.

Industrial and chemical mixers need to be configurable for a wide range of processes, applications, and chemical mixing tank designs. Properly engineered/configured chemical mixers and tank systems will improve the overall chemical process. Eastern Reliability engineers can configure any of our tank systems (HDPE, FRP, and Steel) with mixers to address your industrial chemical process requirements.

Standard and custom industrial mixers are available to meet the varied processing requirements of our customers. In today's market, it's easy to order standard processing equipment online, our goal is to understand what you need to make sure what you're getting is right for your application and customize the product where we can. All mixers come with a standard 3-year warranty.

Top Entry Mixers

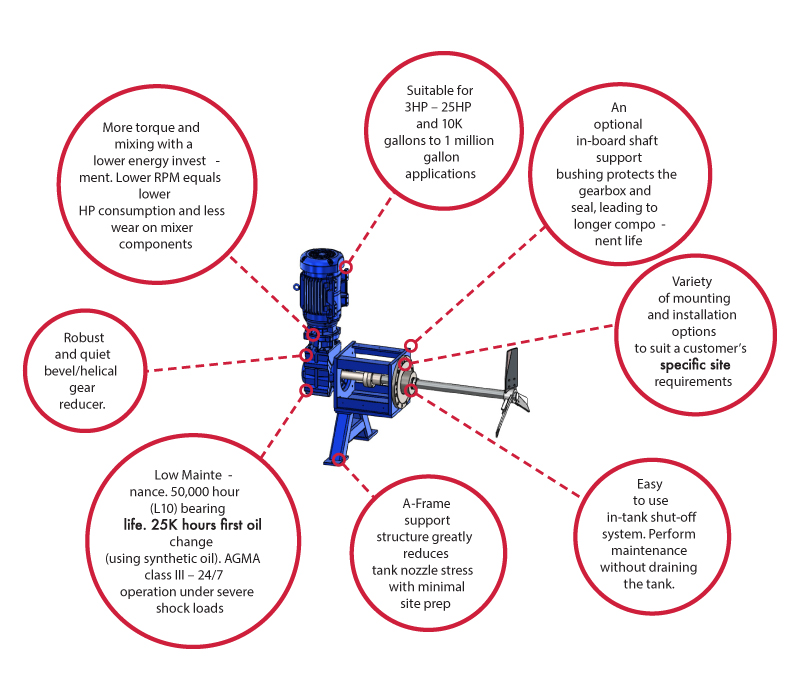

We have provided thousands of these mixers for chemical, petrochemical, industrial, mining, and waste treatment applications where extreme power and durability are essential to the application. These mixers will provide easy maintenance and extended durability for up to 500,000-gallon applications, even if there are high bending and thrust loads on the output shaft. Cleveland Mixer offers one of the most compact drive packages available in top entry slow speed mixers and featuring drywell construction.

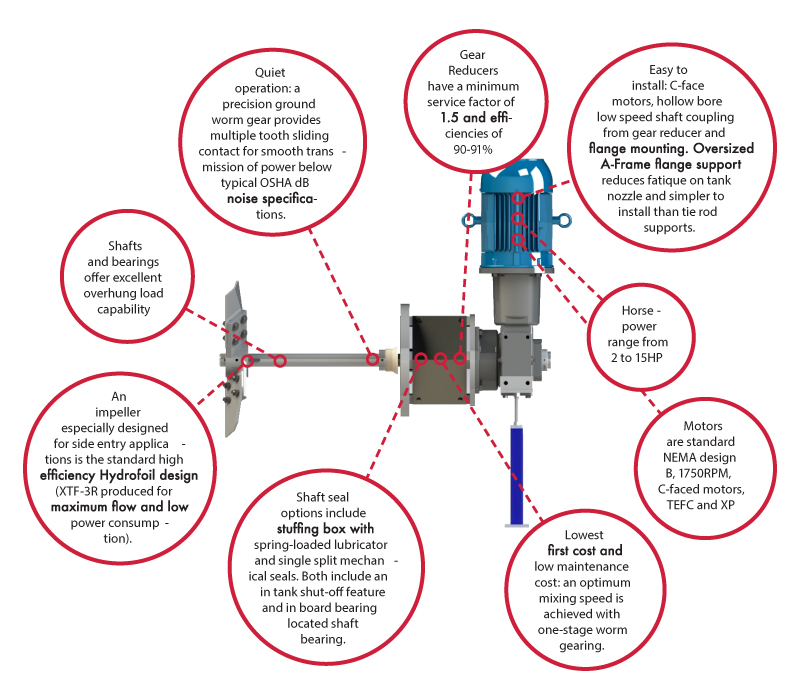

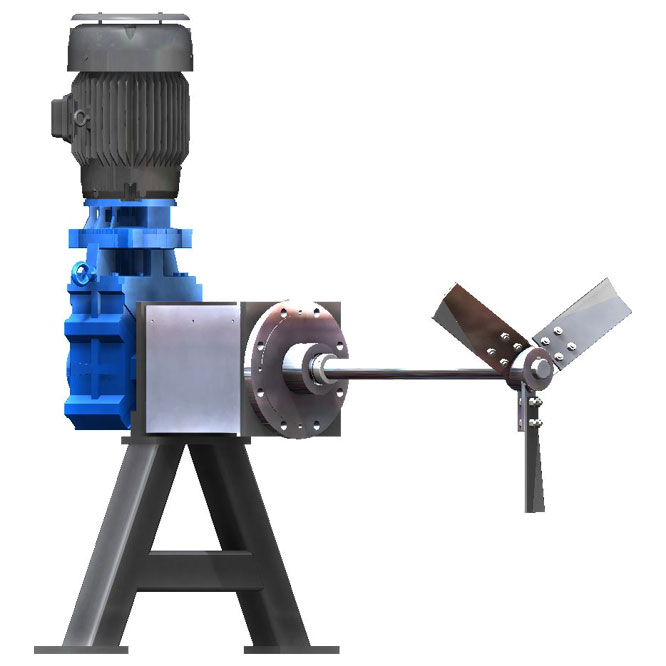

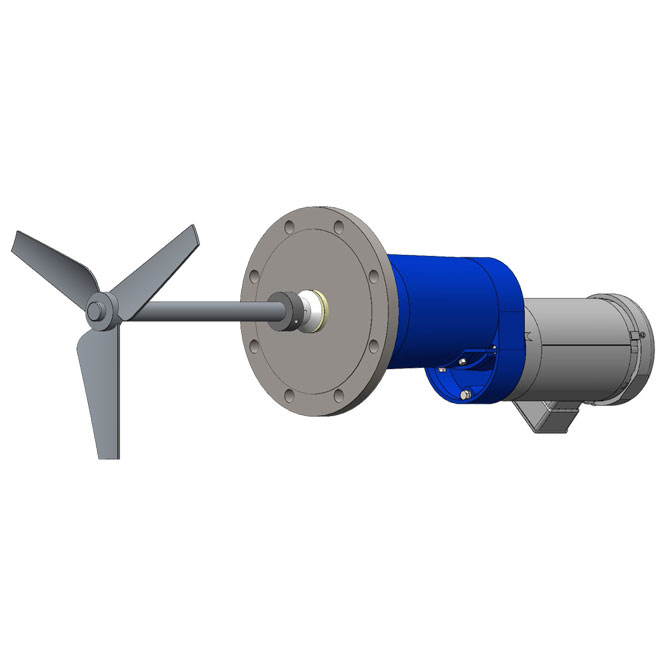

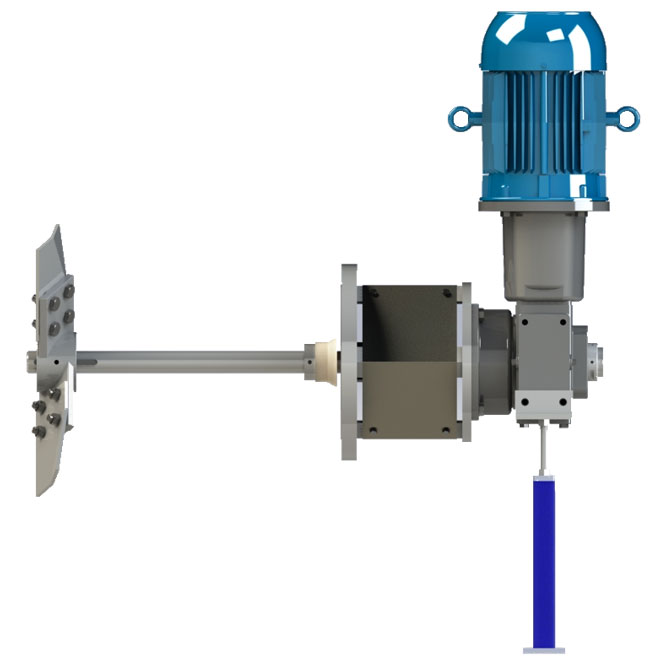

Side Entry Mixers

Our vast lineup of high-efficiency, robust side entry mixers are designed for applications from 1,000 to 1 million gallons. Commonly used for tanks with low headroom, side entry models are less expensive than top entry mixers in large tank installations because the long shafts required by extremely tall tanks are eliminated.

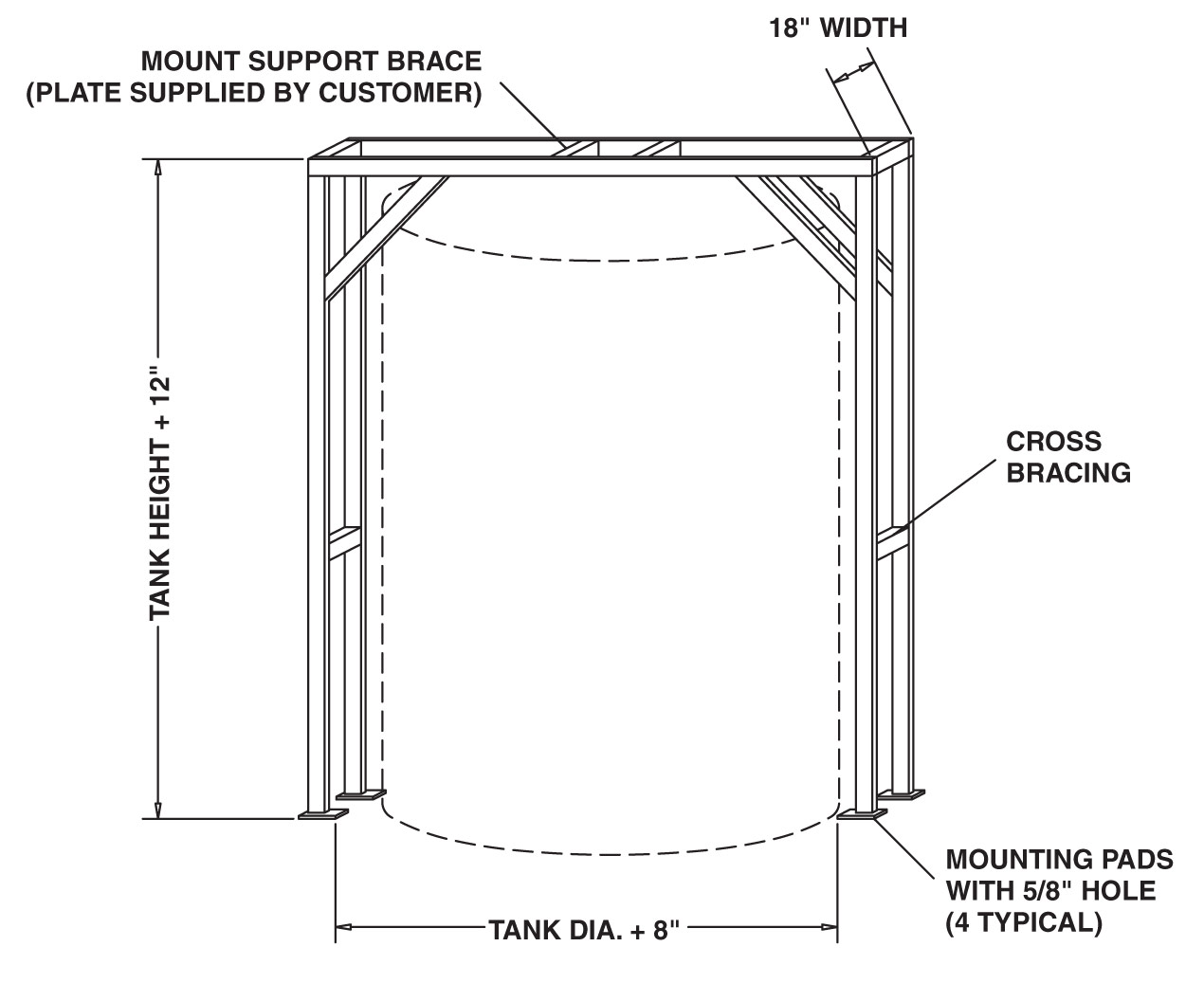

Agitator Support Brackets for Vertical and Conical Tanks

Self-supporting agitator support brackets are designed to handle mixers with horsepower ratings of 3 or 5HP. Agitator support stands are made from mild steel and are epoxy painted as a standard. 304 stainless steel is optional.

Customer to provide mixer mounting holes/bolts or plate onsite. 3HP with 18" mounting support spacing 2" x 2" x 3/16" tube 4" x 6" x 1/4" mounting pads. 5HP with 24" mounting support spacing 3" x 3" x 3/16" tube 4" x 8" x 1/4" mounting pads.

Customer to provide mixer mounting holes/bolts or plate onsite. 3HP with 18" mounting support spacing 2" x 2" x 3/16" tube 4" x 6" x 1/4" mounting pads. 5HP with 24" mounting support spacing 3" x 3" x 3/16" tube 4" x 8" x 1/4" mounting pads.

Custom Tank and Mixer Solutions for Every Application

The ability to mix chemicals is important in certain industrial processes, water and wastewater treatment processes, and agricultural applications. If the primary function of a chemical tank storage mixing system is to properly mix chemicals safely and cost-effectively then it's important to realize that there is no “one size fits all” type of solution when it comes to choosing a mixer.

Here are a few considerations to keep in mind when designing a mixing system for a poly tank.

- What chemicals need to be mixed?

- What are the key components of the mixture?

Certain chemicals may require specialized considerations when designing mixing systems. Larger-size tanks may require that a mixer be mounted directly in the center of the tank with the shaft vertical from a top entry mixer. When a mixer is used in this arrangement, baffles are recommended to prevent the contents of the tank from turning in the direction of the mix which results in a poor mixing condition.

Such baffling will avoid vortexing (pump drawing air from the surface of the liquid) and allow mixing to be as thorough as possible. There are many different types and configurations of baffles that Eastern Reliability can help you specify depending on your application.

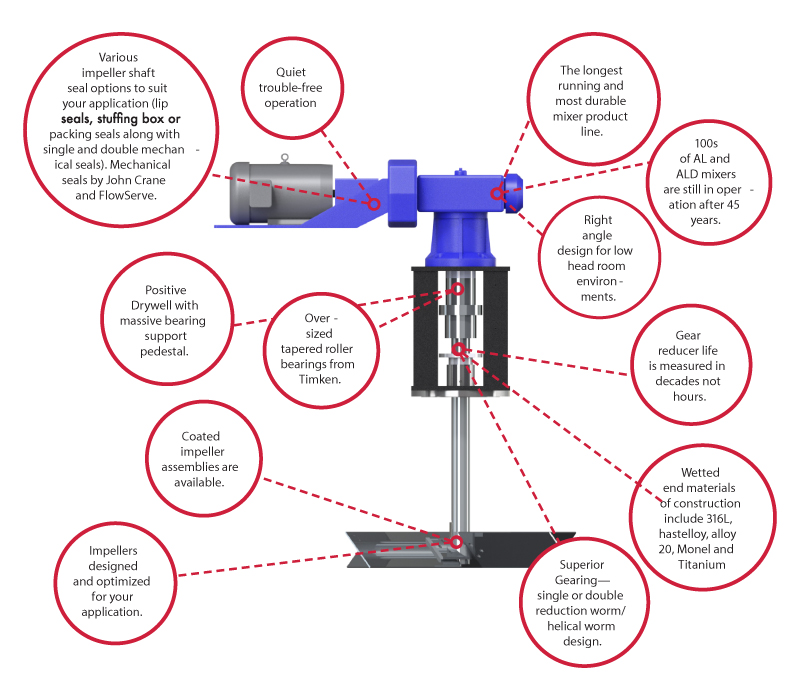

A/BHD Series Right Angle Specifications

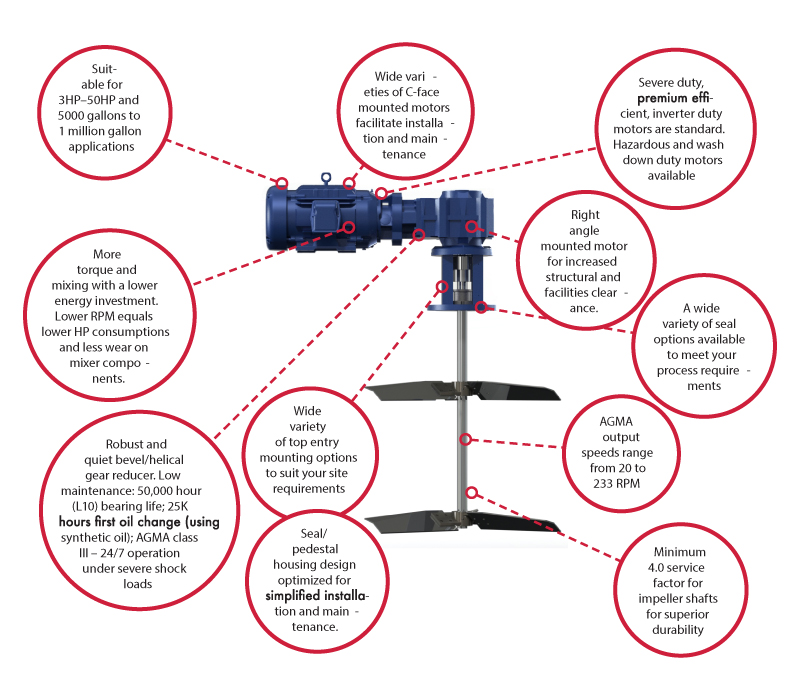

GCD Series Right Angle Specifications

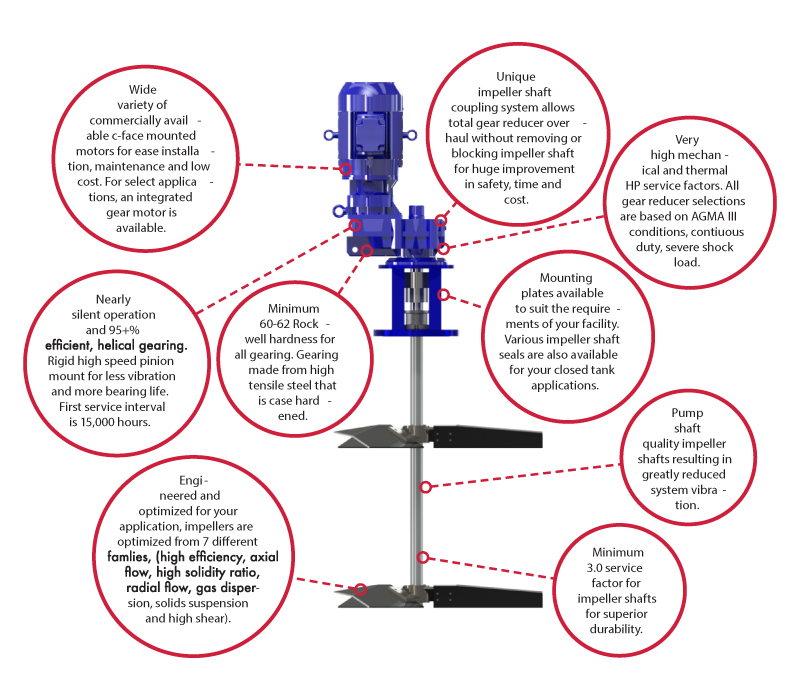

Inline Series Specifications

SFRG Series Specifications

SXT Series Specifications